RAMS: better results in less time

RAMS stands for Reliability, Availability, Maintainability and Safety and defines the functional requirements that a project must meet. RAMS is now a household name in the world of large, complex infrastructure projects and is closely linked to Systems Engineering. It is now unthinkable to carry out a complex project without RAMS analyses. Our experience in the world of infrastructure is that in order for a design to meet the requirements in terms of reliability, availability, maintainability and safety, a tried and tested and systematic approach such as Systems Engineering is indispensable. For large, complex infrastructural projects, this approach also leads to a better way of working together and ultimately to a better result. This has proven itself several times over the past 10 years, even if the store has to remain open and the continuation of business operations has to be guaranteed.

Rams and systems engineering

Major infrastructure projects must be put out to tender at European level. This can be done in a variety of contract forms. Design & Construct, with its long-term management and maintenance attached to it, is more the rule than the exception. Clients want to make sure they get what they want and, in doing so, want to limit their risks.

Systems Engineering has its origins in the military industry and in aerospace but can also be applied to projects in other industrial sectors such as chemicals, oil and gas, transport and logistics, energy and infrastructure projects. The traditional way of thinking in which the complete specifications are laid down in detail from A to Z before the execution starts is thus broken. A Systems Engineering approach also leads to better control of costs and planning in infrastructural projects.

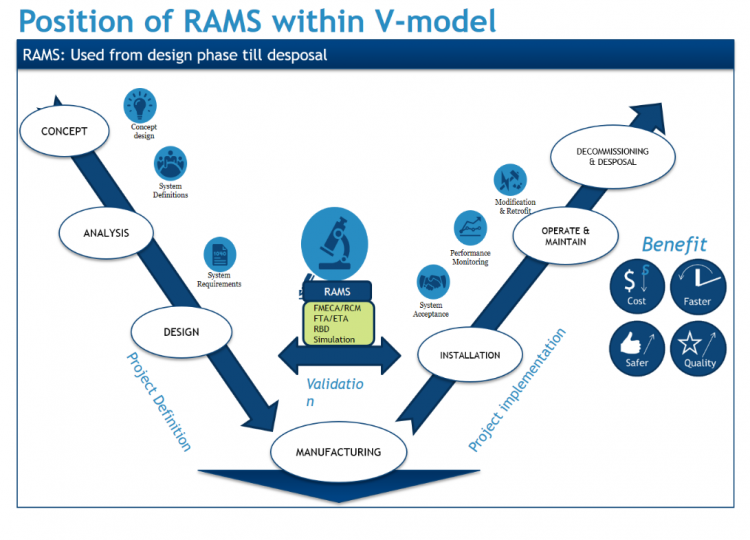

Systems Engineering is based on the V-model, in which the design and execution process are linked together (figure 1). The working method is systematic and all findings are explicitly recorded.

Within RAMS, Systems Engineering is the methodology to translate functional requirements into an acceptable design of a system or object. Acceptable in this case means that the specified reliability, availability, maintainability and safety are met.

The first step is to draw up the RAMS plan, which describes the approach and steps for demonstrably meeting all the requirements of the demand specifications. The RAMS plan describes the demarcation of the project and the system definition, the requirements from the demand specifications of the project, a risk analysis and the verification and validation methods to be chosen. The RAMS manager monitors the structure and the process based on the RAMS plan. Conflicts, deviations and improvement proposals are discussed in the project team and traceably recorded by the RAMS specialist.

In the implementation of the RAMS plan, the RAMS requirements are derived from the demand specifications of the project. These can be functional, technical and process requirements. It is up to the systems engineer to arrange this in a requirements tree and to link it to the object structure. The effort involved is determined by the size and complexity of the project, but certainly also by the quality of the demand specification. If the client has followed the principles of systems engineering in making the demand specification, this process is considerably simpler.

The requirements tree forms the basis for the testing of the design and the realization. Within each phase of the project (design, realization and maintenance), an explicit verification and validation process must be used to test all requirements. In order to demonstrably meet the RAMS requirements, the RAMS specialist uses methods such as FMECA, RCM and fault tree analysis. All systems are thoroughly tested prior to delivery or commissioning. This is done according to a test plan drawn up in advance. Drawing up and executing a test plan is also an integral part of the verification and validation process. The results of the RAMS analysis also form the framework for the design of the maintenance concept.

Prerequisites

An experienced RAMS consultant in your project team provides a demonstrably robust design that focuses on the required level of performance of the system from the design phase onwards. In addition to regulating the formal processes on the basis of the RAMS plan, it is important to be able to discuss issues informally with the client. It helps if the client and the contractor can approach each other easily. RAMS is no longer new in the infrastructure world, but the trick is to apply it carefully in the project so that it proves its added value.