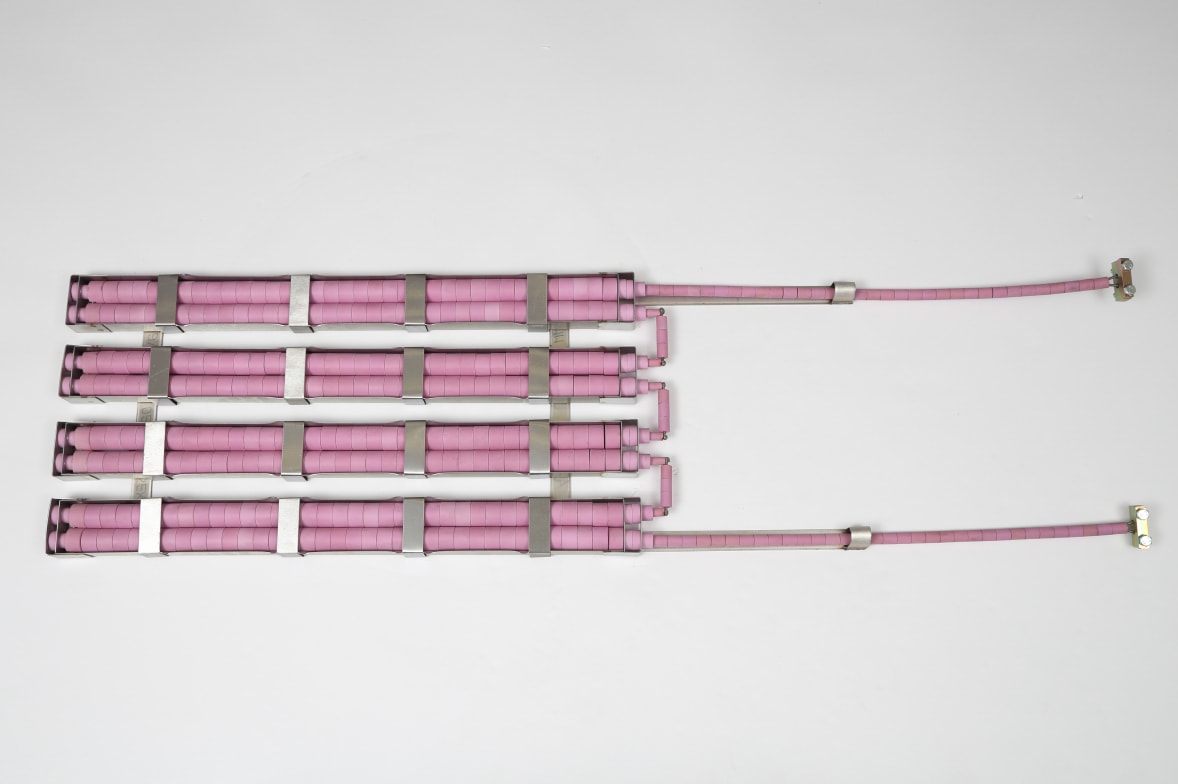

DESCRIPTION

Nickle Chrome 60:16 core (or ICA135), four-bank channel element for post weld heat treatment (PWHT) of large, welded constructions, including steam drums and vessels or for use in furnaces, channel heaters are often more practical than applying large numbers of 60V ceramic heating pad elements. The most common channel element is known as the 4-bank.These elements are powered directly from the incoming 380 V or 415V 3-Phase supply, via a 6-Way, 3-Phase Control trolley (see stock reference 14003).

Channel elements can also be supplied utilising 60V or 80V supplies which can be powered and controlled via standard 60V and 80V output, 50kVA or 70kVA heat treatment machines.

Current: 55 A.

Specifications

| Core Element | Power, kW | Voltage, V | Dimensions, mm |

|---|---|---|---|

| NiCr 60:16 | 13.2 | 240 | 1335×360 |

| ICA135 | 13.2 | 240 | 1335×360 |

Transformer core

- Three phase, forced air cooled, class H, 50kVA

- Primary winding connected in Delta

- Secondary winding connected in Star

- Auxiliary winding: 110V a.c. 3.3kVA single phase

Primary supply

- Primary voltage: 380V, 415V, 440V

- Primary current: 76A, 70A, 66A

- Frequency: 50/60 Hz

Protection

- Three phase 80A circuit breaker with shunt trip

- Three primary core winding over temperature thermostats linked to circuit breaker shunt trip

Secondary outputs

- Output: 32.5V – 0V – 32.5V (for 30V and 60V heating element operation)

- Auxiliary outputs: Two 110V, 10A, 50/60Hz output sockets

- Number of temperature controlled output channels: 6 channels

- Maximum load per output channel: 8.1kW (e.g. three 60V, 2.7kW heating elements)

- Maximum current per output channel: 135A

Switching

- Six double pole, 180A, contractors with 110V a.c. coil

Temperature control

- Temperature measurement, display and control

- Degrees Fahrenheit or Degrees Centigrade

- Start temperature

- Temperature ramp up and down in degrees per hour

- Hold/soak temperature set point and hold/soak time period setting

Temperature recording

- Ambient temperature: Minus 0˚C to 50˚C

- Humidity: 20% to 80% RH, non-condensing is required (temperature x humidity < 3200)

- Environmental protection: IEC IPSO (front door of panel mounted unit)

- Input points: 12 Points

- Input thermocouple types: Thermocouple inputs- K,

- Reference range: Type K: -200˚C to 1370˚C (-326˚F to 249˚F)

- Printing system: Ink jet system, 6 colour

- Chart Width: 180mm

- Chart Length: Z fold 20m

- Chart Speed: 5 to 300mm per hour

Construction

- Case: 304 Stainless Steel case fitted with four 150mm nylon wheels

Dimensions

- Weight: 355kg

- Case Dimensions:

Height: 1545mm

Width: 680mm

Depth: 665mm