Continuous Improvement in performance contracts

Where maintenance is concerned, the urge to achieve Continuous Improvement and learn from mistakes (“don’t make the same mistake twice”) is vital: economically, technically and from the point of view of competition. Greening is an extra motivator for the application of Continuous Improvement: sustainability and Continuous Improvement go hand in hand.

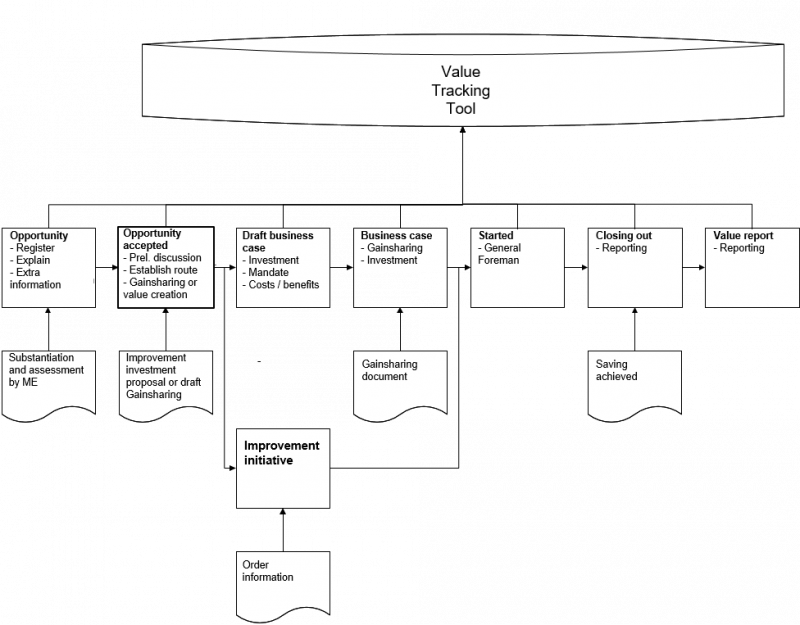

Stork is applying this large-scale improvement method for a client account at Chemolot, among others. Improvement is part of the contract, making it a Service Performance Maintenance subject: a bonus-malus system which sometimes includes the sharing of benefits. We have developed a system for this, which spans the entire process, and have now reached the stage where the first 'fruits' are ready to be 'plucked.’ How does this work in practice and what can you expect to encounter in the collaboration between the Service Provider and Asset Owner?

Employee involvement

Employees are valuable assets: they have the best ideas and initiatives for Continuous Improvement. It all starts with what is in the heads of proactive employees, and this is not always heard. An active suggestions box and linked appraisal system will keep all employees on board with Continuous Improvement: the environment (safety, for example), technique (faster, easier, smarter and greener, for example), losses (less loss), organization (more efficient, doing the right thing, eliminating task duplication) and also performance (more effective, doing the right thing well). In this way, Continuous Improvement can be achieved in the Asset Life Cycle chain, from the initial idea up to and including final scrapping (Crib to Cradle).

Naturally, maintenance also has a professional think tank that continuously occupies itself with the subject of Continuous Improvement. The Service-Providing process with:

- RCAs by employees and feedback;

- the adjustment of plans by applying what has been learned in practice;

- a step back to the maintenance concepts, having the maintenance engineers and reliability engineers properly record the ‘what’ aspect once again.

The professional think tank works just as hard to keep the ideas that employees have on the right track: these need to be developed and gain support at a higher level. However, employees often lack the level of writing proficiency and ability to put their ideas into words: it is often necessary to clarify exactly what an employee means before being able to translate his/her idea into the language of the lender.

Viability

Following the inception and description of an idea, the Maintenance Engineer or Reliability will assess its viability. At this stage, the idea will be developed into an improvement proposal and the following details added: costs, benefits and high-level secondary factors. An idea may be viable, but have a very long payback period or involve very high costs: the viability decision must be made at an early stage in the process, based on certain predetermined guidelines. It is possible that an idea could prove to be worthwhile or viable at a later date.

The initial selection has now taken place and a group of wise people from both the Service Provider and the Asset Owner will discuss each improvement proposal to establish whether it is viable for an improvement initiative, at which point costs and benefits become relevant for the supplier and client, involvement is shared and the interests of both sides become clear. This is one of those times when ‘low-hanging fruit’ should be ‘plucked’ without delay and a business case developed for improvement initiatives involving significant investments, putting lenders in a position to decide whether or not to lend the funds required. The improvement initiative has now become a business case proposal and will be handled on the basis of a more formal approach.

Speed of action becomes relevant at this stage and will vary from one Asset Owner to another. Clearly, more time is needed to consider bigger investments and appreciate their benefits and importance; this is a process that requires patience. Even now, the decision could be made to put improvement proposals on ice, because the time is not yet ripe for them. Usually, the next date for their reconsideration will already have been established. A very practical example of the above is the decision on whether or not to move away from gas-fired equipment: although gas is still cost-effective at the current time, the situation will be very different in three years. An idea has already been put forward on how to improve this situation.

To date, Continuous Improvement has primarily been a paper exercise. The low-hanging fruit can already be plucked (or has already been plucked and then submitted) and improvements converted into savings or benefits. The paper exercise will continue for a little longer, as an exact price tag cannot be determined anywhere at the current time. Once the recommendations in the final business case have been agreed to, the cost side can be established with 10% precision. The price tag will be established on the basis of quotations. Decision-making on implementation can now go ahead, provided it stays within the limits of the final business case.

To properly document how benefits will be shared, the allocation formula must be agreed on in a contract or, for example, via KPIs.

Managment of change

The paper exercise includes the – not to be forgotten - Management of Change process. Although this document is not the right place to discuss this process in depth, it is a fundamental and constantly recurring part of Continuous Improvement: the adjustment of processes, procedures and methods and the implementation of physical technical adjustments all fall under Management of Change (MoC). Initiation of the MoC procedure is often a threshold in itself here. My advice: just get started and do not allow this to put a brake on Continuous Improvement.

After implementing an improvement, the benefit achieved will need to be ascertained, as the allocation of benefits is part of the contract entered into. Agreements on the number of years for which this benefit will apply should be established in advance. This will depend on costs, investment costs, loss of turnover or the decrease in work.

The value tracking cool

Ultimately, both the Service Provider and the Asset Owner will be informed of annual results: have expectations been met or have the KPIs been achieved?

To maintain an overview, it will be essential to use a management tool (the Value Tracking Tool) to keep a record of all of these actions. Statuses, progress, amounts and completion/documentation of all discussions are crucial to the achievement of good management. All reports and, as such, all amounts are based on this.