Get the most out of your Asset Management System

Many capital-intensive installations were put into operation in the last decades of the last century and today require more and more preventive and corrective maintenance to retain their operational reliability. Our clients ask us for a standardized approach in determining the best maintenance strategy in relation to the company's objectives and their derived asset management objectives. In an economically growing market, the uptime of the installation can be important. But legislation and regulations (compliance) can also influence this strategy.

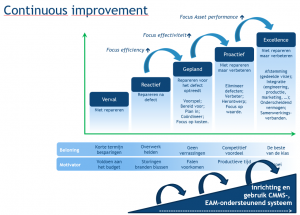

To this end, Stork uses the Asset Management model, on the basis of which the maturity (the ability for continuous improvement) of the maintenance organization is mapped out: from strategy to execution, and from logistics to personnel. In the model, the use of an Enterprise Asset Management (EAM) system (or the relevant modules of an ERP system) is an essential component.

In practice, it appears that many organizations have difficulty getting the right support from the EAM system (sometimes also referred to as CMMS, Computerized Maintenance Management System). Once the choice for an EAM/CMMS system has been made [1] and the implementation has been completed, it regularly becomes apparent that the system does not always meet expectations. For example, it is often difficult to obtain the relevant information from the system and the organization often lacks the knowledge of the EAM/CMMS functionalities. This is usually addressed by introducing so-called workarounds: temporary procedures that, above all, require extra time and manpower.

In this blog we describe why expectations are possibly not met and what can be done about it.

Possible causes (As-Is Situation)

After the purchase of the software, the design of the system design is started, also known as the blueprint. During this design phase, the future work processes, the tree structure, the required reports and the management organization are determined. Practical experience to be able to make the right choices is often lacking, but also the impact of the choices is often not yet clear. For example, the choice of a detailed tree structure may be desirable from a business perspective, but the maintenance of that structure may lead to more administration. There may also be a lack of proper cost insight if the EAM/CMMS does not differentiate according to the nature of the work, e.g. inspections, preventive maintenance, overtime, materials, services provided by third parties and CAPEX-related projects.

If one has gained some experience with the EAM/CMMS system, it turns out in practice that the support of the business processes is quite different from what was originally designed in the blueprint. In addition, business objectives may have changed over time, for instance due to changing market conditions. There is then a need to rearrange parts of the EAM/CMMS or even to start using new - possibly not yet fully set up - functionalities.

Eam/Cmms in line with your business objectives (To-be-situation)

In practice, it is quite a challenge to get the already installed EAM/CMMS in line with the business objectives, whether changed or not. The operation requires a great deal of attention and that, of course, has first priority. But it's also true that EAM/CMMS knowledge is often lacking in order to implement the desired improvements. This means that the improvement can be postponed to the long term, or it cannot or only partially be implemented.

We are seeing that many companies only use a limited part of the available functionality. This does not mean, however, that all functionalities have to be used. Their use depends in part on the company's strategy and the objectives derived from it for Asset Management - in other words, your business drivers. Another aspect is the maturity, more specifically the maturity level, of a maintenance organization, which partly determines the use of the EAM/CMMS.

The desired level of maturity depends on your Asset Management objectives and has an impact on the way the maintenance department works and on the supporting departments. All should strive for the same level of maturity.

By moving to the next maturity level, the degree of use and the design of other functionalities of the EAM/CMMS will also shift. Each level has its own requirements for the design and use of the EAM/CMMS.

By moving to the next maturity level, the degree of use and the design of other functionalities of the EAM/CMMS will also shift. Each level has its own requirements for the design and use of the EAM/CMMS.

Approach

Once the desired maturity level has been determined, a plan can be drawn up based on this to set up the EAM/CMMS. A number of essential issues are important in this respect:

- The tree structure as a functional decomposition

- The work processes for the follow-up of the maintenance activities

- Preventive maintenance tasks for repetitive work

- Quality of the data as source for the EAM/CMMS

- Reports and Key Performance Indicators (KPIs) as a management tool

In addition to these issues, assurance and management are also essential.

Tree structure

Primarily, the tree structure or functional decomposition must match your Asset Management objectives. This tree structure is the coat rack from which almost everything is hung. If it is too general - so it has too few layers - then this has consequences for fault analyses and reporting.

If it is too detailed - so it has many layers - it can lead to unnecessary searching for the mechanics or the person making the error report. Moreover, a tree structure with many layers requires a lot of maintenance on this structure in the EAM/CMMS.

Changes and/or expansions in the installations will have to be included in the tree structure during the lifetime. This is where there is a link with the change procedures. If the tree structure is not maintained and no longer corresponds to the current situation, the EAM/CMMS operation will be adversely affected.

Work processes

The design of the work processes is just as important as the tree structure. In addition to recording all reports related to the installation in the EAM/CMMS, monitoring them in the form of work orders is at least as important. This provides transparency in the planned, ongoing and performed work, which in turn contributes to the demonstrability during audits, for example. What's more, signing off on work orders as well as registering findings on these orders are essential in order to start up periodic analyses and improvement processes.

Preventive maintenance tasks

An EAM/CMMS system is ideal for initiating and managing repetitive work such as Preventive Maintenance Tasks. What is important here is for what type of installations these tasks have been defined and how the activities have been described. Of course, the frequency with which the work has to be carried out also plays a role.

At the very least, tasks must be present for the critical installations; critical from a safety point of view as well as from a business process point of view. Of course, tasks must also be in place in order to comply with the statutory requirements (e.g. those of demonstrability).

Setting up and entering these tasks in the EAM/CMMS requires an investment, but ultimately saves work and ensures transparency of the work to be carried out. Moreover, this is an additional tool to safeguard the available knowledge in the company, especially in a time of an aging population and the increasing scarcity of labor.

Within the framework of strategies such as TPM (Total Productive Maintenance), tasks like those of a production department can also be included. Example might be inspections, sampling and cleaning of the installation. This makes the EAM/CMMS not only a system of the maintenance organization, but also a system of production, which will benefit the wider acceptance of the system.

Data quality

It goes without saying that, in addition to the design, data quality is also important. This is an essential part of being able to continuously improve and (re)steer. This requires, for example, correct feedback on the work carried out in terms of turnaround time and hours used, materials used and findings. If the data quality is not in order, this has an effect on the reports and KPIs that are generated, which can result in decisions being based on incorrect information.

In addition to the importance of data quality in general, master data management (e.g. materials and supplier data) is also crucial. If this information is incorrect, the system will be contaminated in no time, with all the consequences that this entails.

Reports and kpis

The EAM/CMMS is not only intended to register the maintenance activities and to facilitate their execution. The available data is an excellent tool to analyze the work carried out and to implement process improvements. However, there is always a temptation to generate all kinds of reports and KPIs in this context and to disseminate them widely. It is more effective to see for each target group or role which reports are really needed and to generate only those reports that contribute to the objectives of that target group or role. In this way, everyone only receives the reports that are necessary for the proper performance of his or her role and from which influence can be exerted in order to realize improvements.

Assurance and management

As mentioned earlier in this blog, a properly implemented system is no guarantee that the system will be used as intended both now and in the future. This means that periodic checks must be made to ensure that the work agreements and procedures are being complied with, that the data quality is in order and that the application knowledge in the organization is still at the desired level.

This requires good management organization. The management roles must be properly defined and implemented. By doing so, we ensure adequate support in working with the application, gain insight into possible shortcomings and keep a close eye on new developments, such as modified/new functionalities, mobile working and the use of apps.

By checking these topics and taking action if necessary, you can bring your EAM/CMMS back into line with your Asset Management objectives. This process all starts with the central question: “Are you getting the most out of your EAM system?”

[1] This article is a sequel to the previously published blog about EAM/CMMS selection.